Product Center

Product Center

Composite fluid collector coating machine

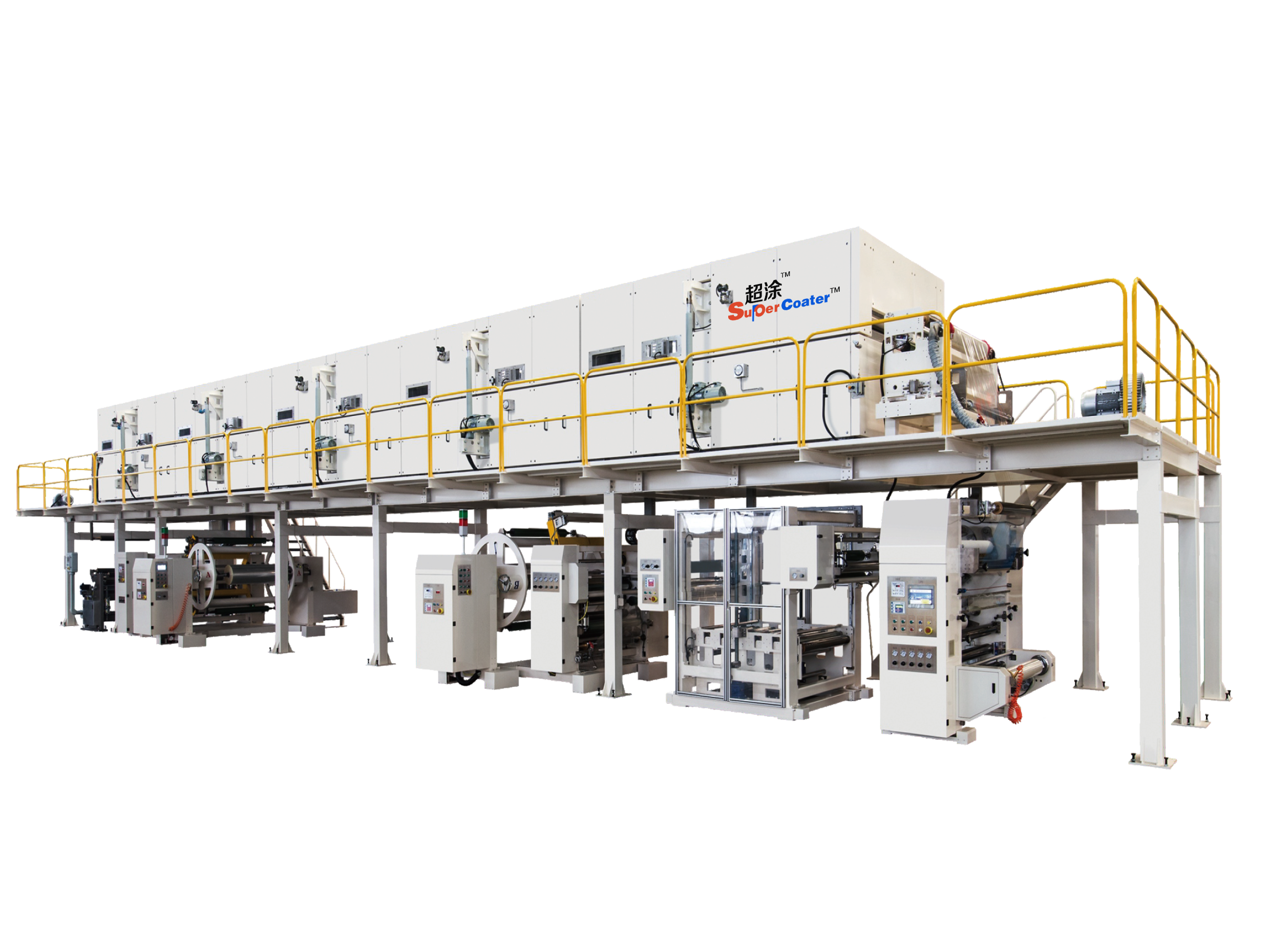

SuperCoater™ Disrupting the current production process route of composite fluid collectors:

Adhesive method (coating+bonding+pressing)

Key points for coating design of composite fluid collection base film:

1) Unwinding: core, coil diameter, tension, correction, flattening

2) Traction: speed, tension, flattening

3) Coating head: type, thickness, accuracy

4) Oven: heating mode, transmission mode, efficiency, speed, tension, flattenin

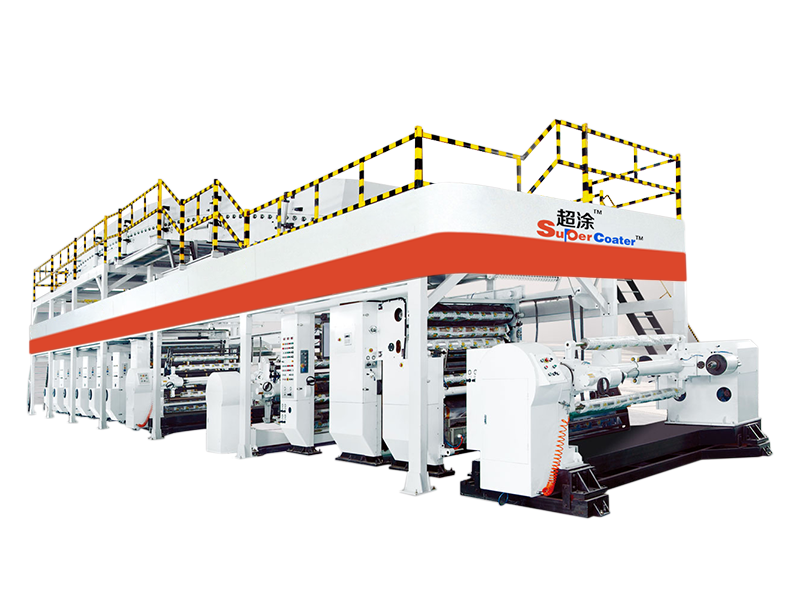

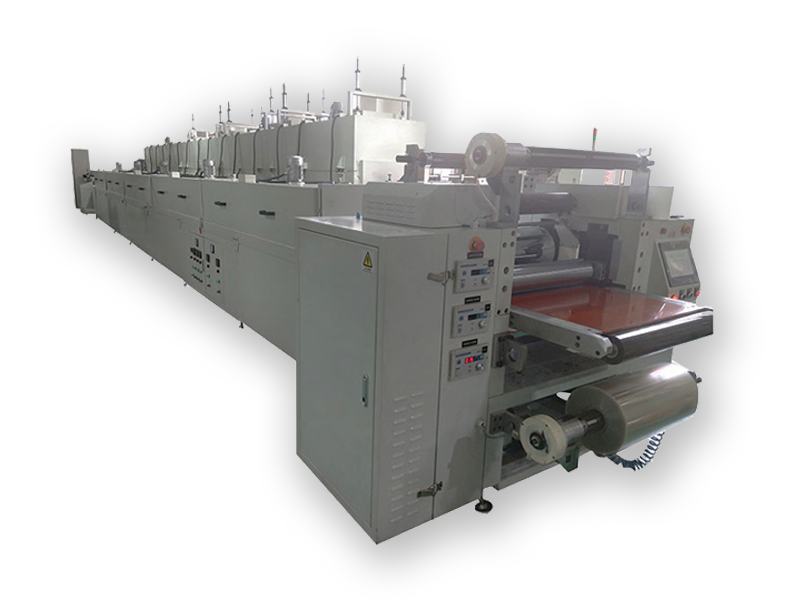

Environmentally friendly paper coater

1. Comma roller coating machine (scraper coating machine);

2. A brand new curved oven baking design with independent temperature control for each section, improving quality assurance;

3. Adopting independent correction system for winding and unwinding technology, achieving stable operation, neat and no deviation;

4. Independently developed a new electrical control system with closed-loop tension control for floating rollers, ensuring stable low-speed and low

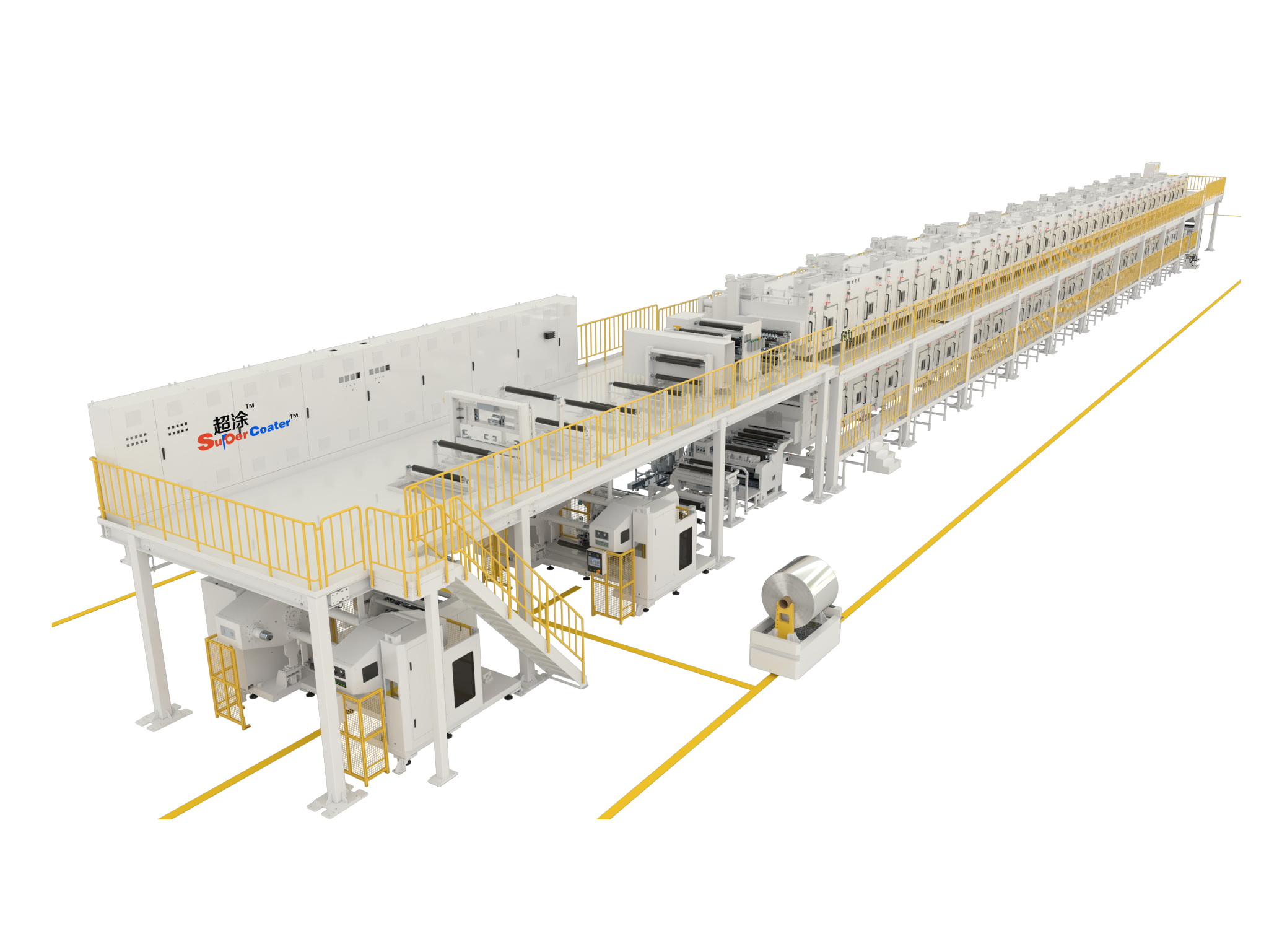

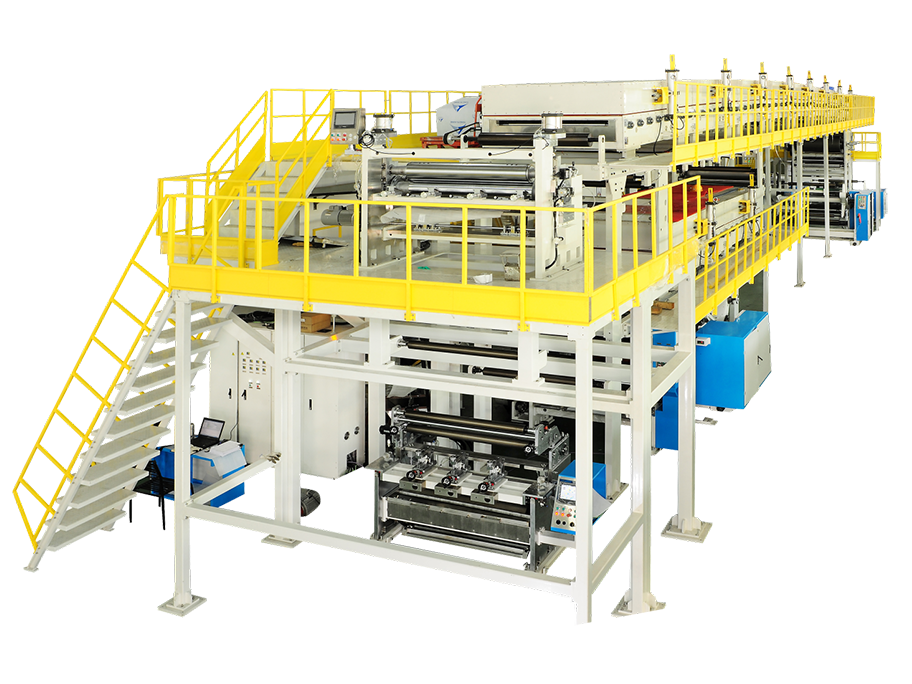

High speed double layer extrusion coater

1. The surface density meter and the mold head can form a closed-loop control;

2. CCD size closed-loop control;

3. Siemens bus control mode;

4. Apply termination adhesive to the tail material;

5. It is possible to apply double-layer materials on the same side of the substrate;

6. MES linkage, remote cloud control equipment.

7. Surface density meter X/ β Ray online monitoring of surface density;

8. CCD size detection and defect detection

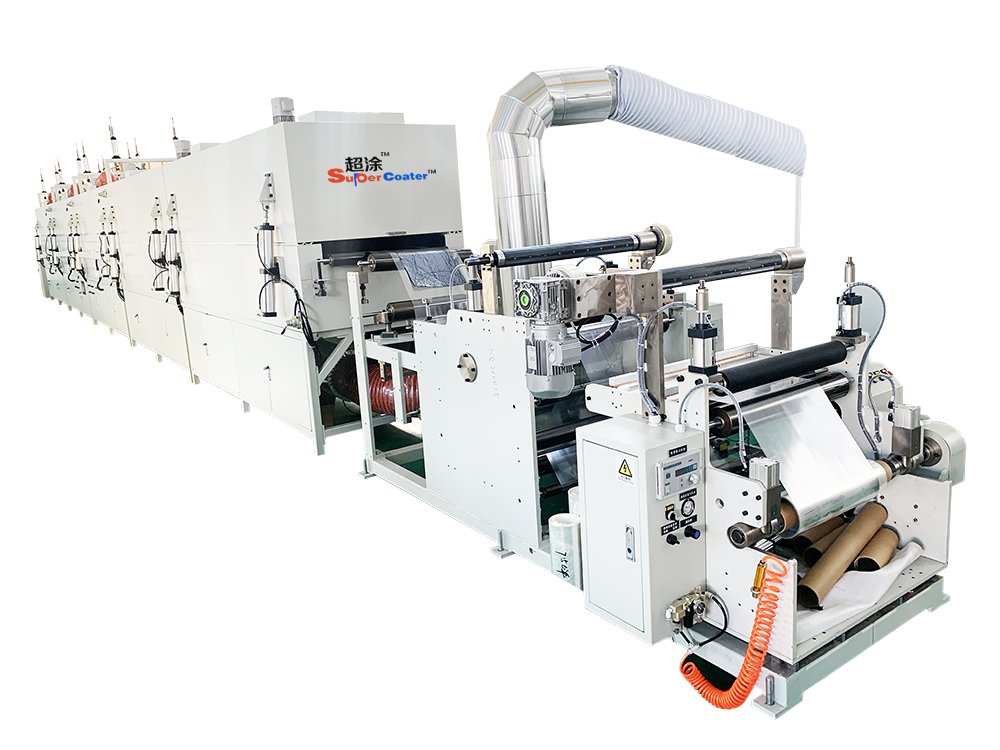

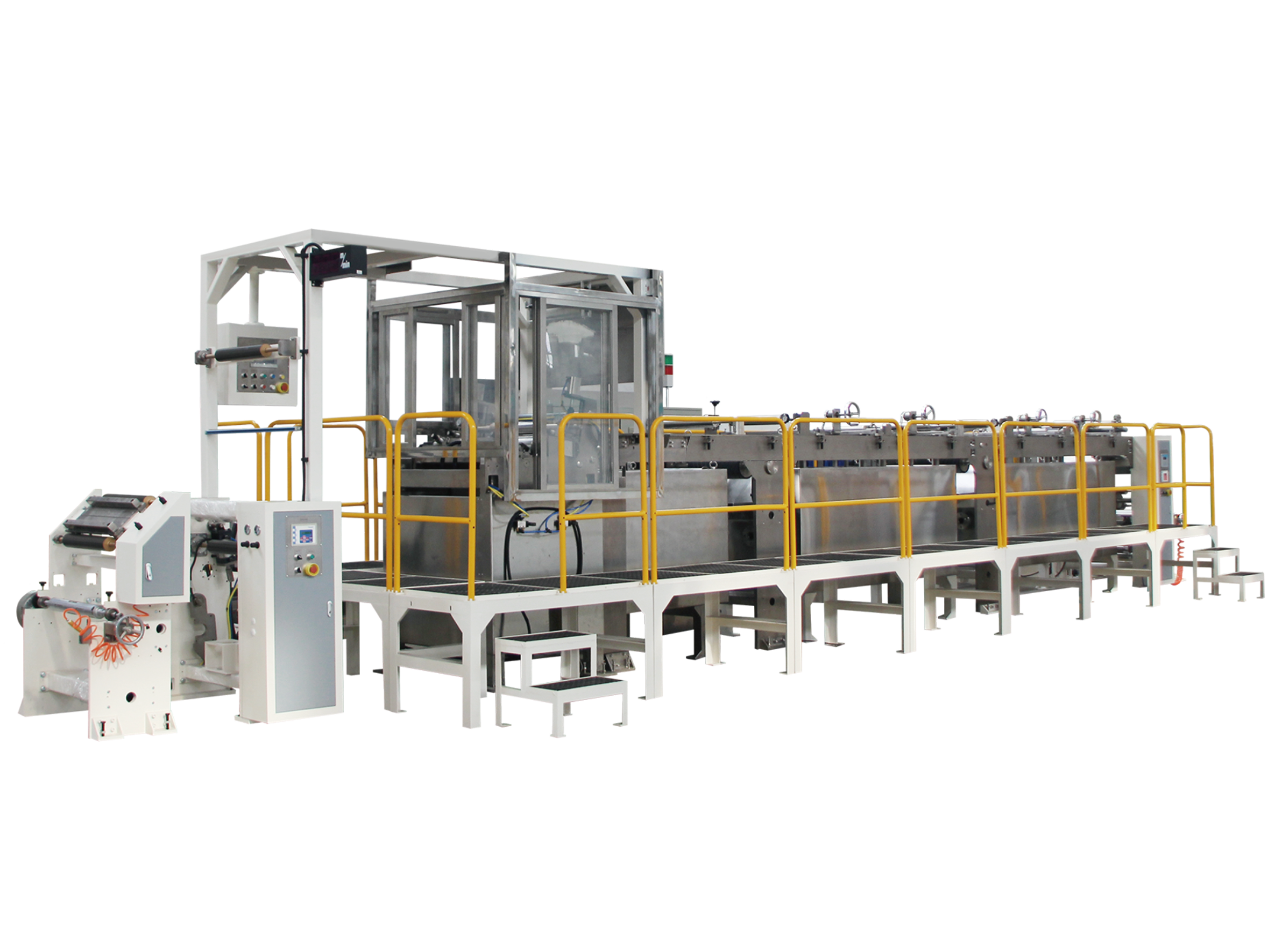

Hydrogen fuel cell carbon paper coater

1. It can quickly and massively produce carbon paper, improving production efficiency;

2. The prepared carbon paper has a uniform thickness, smooth surface, and stable and reliable quality;

3. Independent feeding base, easy to operate, with good automatic correction effect;

4. The unwinding/rewinding process adopts a magnetic powder brake (clutch) combined with a tension controller to achieve automatic tension control and save labor;

5. The coating p

Water-based paste graphene coater

1. Programmable PLC integrated control, touch based human-machine interface operation, intuitive and clear, convenient and fast;

2. Adjustable coating amount and precise control of coating accuracy;

3. Fully automatic tension segmented control, synchronous operation of the entire machine;

4. Multi point automatic correction to ensure the neatness of the winding process;

5. The oven adopts energy-saving box type fans with high drying efficiency, and ad

Hydrogen fuel cell proton film coater

1. Proton membranes can be produced quickly and in bulk, improving production efficiency;

2. Able to prepare high-quality proton membranes as one of the core components of hydrogen fuel cells, used to transfer hydrogen ions from the anode to the cathode, while preventing direct contact between the electrolyte and gas;

3. The prepared proton membrane and diaphragm have uniform thickness and stable quality, which can meet the p

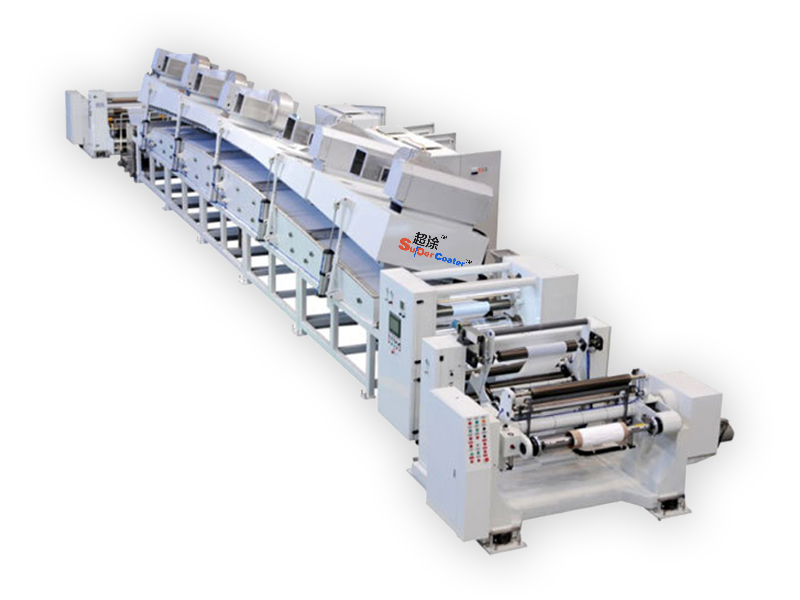

Double-sided diaphragm coater

Coating method: Micro gravure continuous coating/rotating nozzle coating

Coating speed: MAX: 100-150m/min

Coating width: MAX: 1500mm

Winding tension: 3-5 N

Coating thickness accuracy: ± 0.3 μ M

Single sided coating dry thickness: 0.5-10 μ M

Substrate thickness: 5-20 μ M

Roll diameter/weight: MAX: Φ 400mm/100kg

High frequency copper-clad coater

1. The price for the same production capacity is one-third of that of similar equipment;

2. Compared to the same period last year, the production efficiency of similar equipment worldwide has increased by 300-500%;

3. Unique heating and drying technology, with an efficiency increase of 3-5 times compared to peers (depending on the raw material formula);

4. Compared to the same period last year, the production energy consumption of similar equipment worldwide

Special tape coater

1. The price for the same production capacity is one-third of that of similar equipment;

2. Compared to the same period last year, the production efficiency of similar equipment worldwide has increased by 300-500%;

3. Unique heating and drying technology, with an efficiency increase of 3-5 times compared to peers (depending on the raw material formula);

4. Compared to the same period last year, the production energy consumption of similar equipment worldwide

Single layer high speed extrusion coater

1. Suitable for gap coating and compatible with insulation adhesive coating process

2. Simulate and optimize the design based on the air and temperature fields of the oven

3. Optional dual pump feeding, size monitoring, electrode temperature measurement, automatic air valve adjustment and other functions

Double layer intaglio undercoating machine

1. The coating of bottom modified materials suitable for lithium battery substrates can achieve continuous, intermittent, and zebra coating, and can be used in conjunction with electrode coating machines;

2. Series coating on both sides, achieving double-sided coating in one go;

3. By carving different patterns on the gravure roller, different coating styles can be achieved;

4. The diameter range of the gravure roller is D200~650mm, suitable for the mainstre

Proton exchange membrane coater

1. The price for the same production capacity is one-third of that of similar equipment;

2. Compared to the same period last year, the production efficiency of similar equipment worldwide has increased by 300-500%;

3. Unique heating and drying technology, with an efficiency increase of 3-5 times compared to peers (depending on the raw material formula);

4. Compared to the same period last year, the production energy consumption of similar equipmen

Alkaline electrolytic water composite diaphragm

1. The price for the same production capacity is one-third of that of similar equipment;

2. Compared to the same period last year, the production efficiency of similar equipment worldwide has increased by 300-500%;

3. Unique heating and drying technology, with an efficiency increase of 3-5 times compared to peers (depending on the raw material formula);

4. Compared to the same period last year, the production energy consumption of similar equipment worldwide

Reconstituted tobacco coater

1. The price for the same production capacity is one-third of that of similar equipment;

2. Compared to the same period last year, the production efficiency of similar equipment worldwide has increased by 300-500%;

3. Unique heating and drying technology, with an efficiency increase of 3-5 times compared to peers (depending on the raw material formula);

4. Compared to the same period last year, the production energy consumption of similar equipment worldwide

Copper foil aluminum foil carbon coater

1. The price for the same production capacity is one-third of that of similar equipment;

2. Compared to the same period last year, the production efficiency of similar equipment worldwide has increased by 300-500%;

3. Unique heating and drying technology, with an efficiency increase of 3-5 times compared to peers (depending on the raw material formula);

4. Compared to the same period last year, the production energy c